This New Technology Could Change Toyota's EV Production Forever

The technology behind car production has come a long way over the years with assembly lines that require fewer workers and automation that allows companies to produce more vehicles in less time. But a new technology could cut that time by half and change the way vehicles are made across the industry.

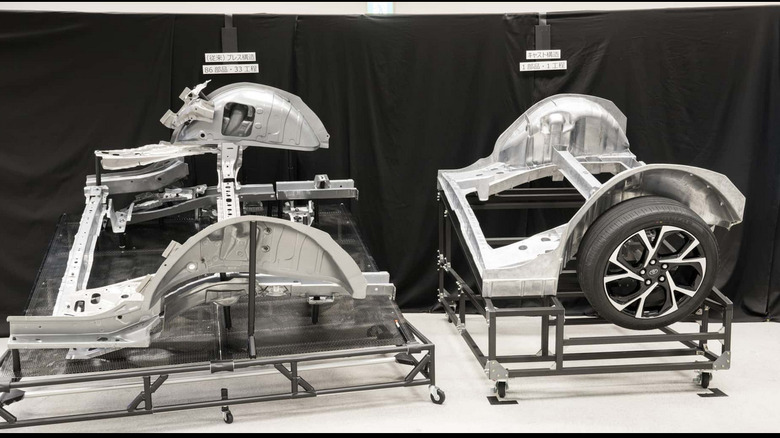

Toyota Motor Corporation recently took a massive leap towards faster electric vehicle production by implementing Gigacasting. This technology was initially used at Tesla production facilities and makes it possible to build more significant pieces of the chassis at one time instead of assembling multiple parts on their own. By 2026, Toyota hopes to use the technology to create large sections of its new electric vehicles, while cutting down on production times.

With Gigacasting, Toyota hopes to ramp up electric vehicle production substantially, with a goal to produce 3.5 million cars per year by 2030, according to Nikkei Asia. It also hopes to make it possible to build an entire vehicle from a process that now takes 10 hours down to just five hours per car.

The Gigacasting process

The chassis of a vehicle is what holds all the components needed for it to be a car. It's the metal underbelly and frame to which all the components are attached, and it needs to be molded in such a way that each piece will fit perfectly. Gigacasting is the process of using very high-temperature aluminum and a casting mold to create large pieces of the chassis. What once required separately assembled pieces then could be combined into a much larger mold, thereby taking much less time to manufacture.

While Gigacasting has many benefits, it's not without downsides. One of the biggest issues is that if you get into an accident, a mechanic won't be able to replace solely affected components anymore. Fixing that larger piece could mean bigger repair costs for your car or more time in the shop waiting for a replacement.

EV production ramping up

Toyota reportedly sold close to 25,000 electric vehicles in 2022. They are hoping to sell 3.5 million in 2030. Gigacasting will be largely responsible for how Toyota gets to that number, because they'll be able to pump out cars in a fraction of the time that it takes now.

Indeed, now that Tesla has illustrated success with this particular building process and Toyota is jumping on the bandwagon, it is possible that other car companies may follow suit. After all, speeding up the manufacturing process means more cars sold and more money made. Several others have already begun upgrading their factories (or plan to soon) including General Motors, Hyundai, Mercedez-Benz, and Volkswagon. With Gigacasting, the auto industry will be able to ramp up production and perhaps make way for more affordable electric vehicles in the future.