The 10 Most Reliable Diesel Engines Ever Built

The diesel engine dates back to the 1890s when Rudolf Diesel, a German inventor and mechanical engineer, created the powerplant for use in commercial power generation applications. The design (compression-ignition engine) ignites fuel when mechanical compression elevates the air temperature in the cylinders. Diesel engines do not require spark plugs used in conventional internal combustion engines.

Over the past 40 years, the diesel engine has become a significant source of power in trucks and automobiles. When gas prices skyrocketed during the oil crisis of the 1970s, diesel-engine models boasting superior fuel economy became even more popular. In recent years, sales of Diesel vehicles in the U.S. have declined while automakers are promoting the sales of EV and hybrid vehicles. However, in 2021, diesel sales in Europe and Britain still made up more than 20% of new cars sold.

While oil burners typically run for up to 350,000 miles without significant deterioration, according to Motor Verso, the best diesel engines can last much longer. Here are 10 of the most reliable diesel engines ever built.

6.6L Duramax LB7

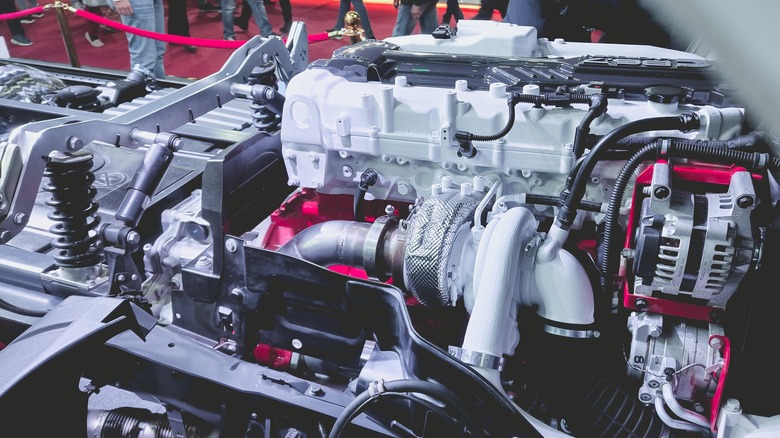

General Motors (GM) introduced the 6.6-liter Duramax LB7 in 2001 as a replacement for the Detroit Diesel Corporation (DDC) V8 engine helping establish the automaker as a legitimate competitor in the diesel marketplace. With built-in collaboration with Isuzu, the LB7 was a state-of-the-art 6.6-liter V8 with four-valves-per-cylinder producing 235 to 300 hp and 500 to 520 lb-ft of torque (best in its segment).

In addition to a turbocharger and intercooler, GM introduced the LB7 Duramax with an innovative new technology, the Bosch Common Rail Injector. The high-pressure rail combines the pump and injectors to create a central hydraulic component that stores the compressed fuel and supplies it to the injectors. The Duramax design also employed lightweight aluminum alloy cylinder heads well ahead of its closest competitors. Ford did not introduce aluminum cylinder heads until a decade later when it debuted the 6.7-liter Powerstroke in 2011.

Although the GM had problems with the early fuel injection systems, the units were replaced with improved versions and the automaker offered buyers a 200,000-kilometer guarantee on the injection system. GM installed the Duramax in the first-generation Chevrolet Silverado HD and GMC Sierra HD. Considered one of the most durable and affordable diesel engines of its time, the power plant is also known for its reduced emissions.

BMW M57 Engine

The BMW M57 is a six-cylinder engine and perhaps the automaker's best diesel ever. In road cars, it typically produces from 150 hp and 221 lb-ft of torque to 286 hp and 580 lb-ft of torque, while the Dakar rally car version generated 320 hp and 580 lb-ft of torque. Produced from 1998 to 2010, BMW made the M57 with three different displacements:2.5, 2.9, and 3.0-liters paired with a variety of exceptional accessories, including a variable geometry turbocharger, Bosch injector, diesel particulate filter, and a double mass flywheel.

However, the Common Rail injection system is perhaps the feature that pushed the engine to the top of the best diesel ever made list. It replaces the previous mechanical injection pump with a state-of-the-art high-pressure fuel rail. Pressures of up to 26,000 PSI guarantee that the diesel fuel is completely atomized resulting in a more efficient and cleaner combustion.

In 2008, the German automaker introduced the diesel engine to the U.S. market in the BMW 335d equipped with a unique sequential turbo arrangement that helped produce 265 hp and 425 lb-ft of torque. The sporty sedan accelerated to 60 mph in an impressive (for a 6-cylinder) 5.7 seconds and reached the quarter mile in just over 14 seconds. BMW installed the M57, rated to last 600,000 km, in several models including the BMW 3, 5, 6, and 7 Series, X Series, and the diesel engine also powered the Opel Omega B FL (C), and Land Rover Range Rover III (L322).

Ford 6.7L Power Stroke Diesel Engine

Ford Motor Company introduced the 6.7-liter Power Stroke diesel engine in 2011. Developed "in-house," the engine replaced the 6.4-liter Power Stroke manufactured by International Navistar. It was the first Power Stroke engine not supplied by International Navistar for over 30 years.

The 6.7-liter Power Stroke diesel has proven to be extremely durable, and reliable. However, as with all engines, a few issues have been reported, but none severe enough to tarnish the power plant's reputation. Turbochargers are often the most likely source of engine problems, and the early Power Stroke models were no exception. Ceramic bearings on the turbo shaft were prone to premature failure, but Ford changed them to more reliable steel ball bearings in later versions. Early model engines used four bolts per cylinder holding down the cylinder heads. Later models changed to six bolts per cylinder, greatly reducing the risk of head bolt stretch and blown head gaskets that allowed coolant and oil to enter the cylinders.

For 2023, Ford continues its top-of-the-class diesel power offering its Super Duty pickup with two Power Stroke V8 diesel engine options (in addition to two gasoline engines). The 6.7-liter Power Stroke diesel generates 475 hp and 1,050 lb-ft of torque while the high-output (HO) Power Stroke produces 500 hp and an impressive 1,200 lb-ft of torque. The HO version hauls up to 8,000 pounds of payload and tows up to 40,000 pounds equipped with a gooseneck trailer.

Mercedes 2.1 OM611 Engine

The Mercedes 2.1 OM611 engine is the four-cylinder version of the diesel engine series that includes the OM 612 and OM 613 with five or six cylinders, respectively. All three are in-line engines with common features. They have the same cylinder capacity, and are equipped with the same injectors, pistons, connecting rods, valves, and other components. All the engines are built with cast-iron blocks and feature aluminum cylinder heads with four valves per cylinder.

Produced from 1997-2006, the OM series engines feature common rail injection with Bosch injectors. In the Mercedes CDI Series II cars, the injection system uses a mechanical fuel feed pump, a pressure control valve, a flow control valve, and a fuel temperature sensor to manage the high pressure. The 2.2 CDI OM611 Engine produces from 82 to 143 hp and is rated to last 600,000 km (over 372,000 miles).

Mercedes installed the 2.1 OM611 engine in the C-Class W202, W203, CL203, E-Class W210, V-Class W 638, and Sprinter W901. Mounted in a 1997 Mercedes C 250 Turbodiesel, the five-cylinder OM 612 diesel connected to a five-speed manual or automatic transmission produces 148 bhp at 4,400 rpm and 207 lb-ft of torque at 1,800 rpm. The BMW with a curb weight of 1,480 kg accelerates to 62 mph in 10.2 seconds and reaches a top speed of 126 mph and has an estimated fuel economy of 35.3 mpg.

Chrysler 3.0L EcoDiesel

Fiat Chrysler Automobiles (FCA) introduced the 3.0-liter EcoDiesel engine in 2011, offering it to the European market. In North America, the automaker provided the L630 DOHC version in 2014 for the Ram 1500 and Jeep Grand Cherokee.

VM Motori, a subsidiary of Fiat Chrysler in Cento, Italy, built the 3.0-liter EcoDiesel with a graphite iron (CGI) engine block making it more compact, stronger, and lighter than an engine using a cast iron block. For additional strength, FCA bolted a bedplate to the engine block, and inside installed an upgraded crankshaft made of forged 4140 steel. The manufacturer also installed high-strength cast iron connecting rods, and lightweight cast aluminum pistons for durability. The six-cylinder engine boasts aluminum DOHC heads with four valves per cylinder, and low-voltage ceramic glow plugs give the engine quick starts and reduced emissions.

The 3.0-liter EcoDiesel engine features a high-pressure direct injection fuel system known as MultiJet II, and it employs a water-cooled Garrett variable geometry turbocharger (VGT). Like most modern diesel engines, the EcoDiesel is also fitted with a variety of emission reduction equipment, such as a Diesel Oxidation Catalyst (DOC) and a Diesel Particulate Filter (DPF). From 2014 to 2019, the 3.0L EcoDiesel produced up to 240 hp and 420 lb-ft torque. In 2020, FCA boasted added power of 20 hp and 60 lb-ft torque.

The performance, durability, and reliability of the 3.0-liter EcoDiesel engine earned it Ward's "Ten Best Engines" for three consecutive years in 2014, 2015, and 2016. The engine's success inspired Ford to introduce the 3.0-liter V6 Power Stroke engine and GM the 3.0-liter I6 Duramax engine.

Honda 2.2 CTDi Engine

Although Japanese car manufacturers typically purchased diesel engines for their cars before 2003, Honda began production of its own N22A1 diesel engine named the 2.2 CTDi in the same year. The engine was a popular choice in the Civic VIII and Accord VII, generating 140 hp and 250 lb-ft of torque.

The four-cylinder, 16-valve engine has a chain-driven camshaft, common rail fuel injection system with Bosch injectors, variable geometry Garrett GTA1752LV turbine, and a double mass flywheel. The engine complies with the Euro 4 emissions standard. The engine has a rated durability of 600,000 kilometers and has an approximate engine life expectancy (before serious repairs) of 220,000 to 370,000 kilometers. A realistic engine life expectancy depends on the regularity of maintenance and the quality of the materials used.

However, even a well-maintained CTDi engine can have problems, though such issues are typical of diesel engines. The supercharger is subject to premature failure of shaft bearings and the EGR valve is prone to clogging, especially in cars driven mostly in city traffic. These issues can result in a decrease in power, uneven engine performance, and excessive smoke. Installed in a Honda CR-V, the 2.2 CTDi Engine seems a bit underpowered. Car and Driver tests showed the compact SUV accelerating to 60 mph in a lethargic 9.4-seconds but is only 0.3 seconds slower than the category average. Performance improves once the turbo spins up and the fuel efficiency is rated at 28 mpg while the highest recorded average for a gas-fueled CR-V is 22 mpg.

Ram Cummins 6.7L Engine

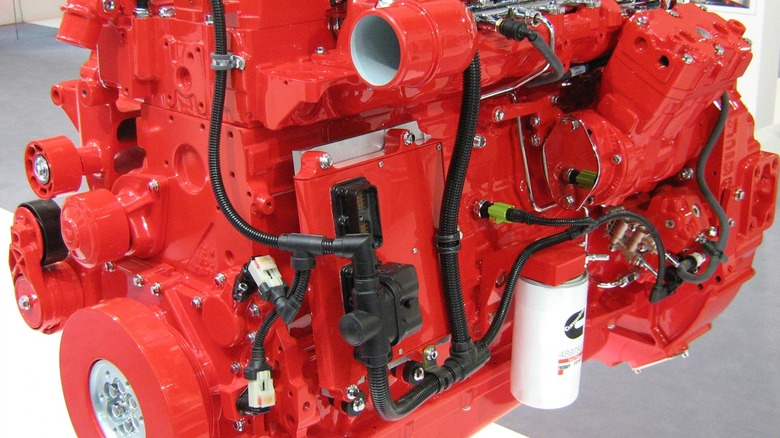

Cummins has a long history of building diesel engines for Ram beginning in 1989. The relationship started with the reliable and efficient 5.9L Turbo Diesel, which held prominence for two decades before being replaced with the 6.7-liter Cummins Turbo Diesel. In 2007, Ram installed the new diesel in the Dodge Ram 2500 and 3500 Heavy Duty pickup trucks in commercial models including the Chassis Cab 3500, 4500, and 5500, and in the Ford F-650 and F-750 medium-duty trucks.

Over the past 16 years, the 6.7 ISB has carried on the tradition established by the 5.9L Turbo Diesel as a reliable engine capable of exceptional performance. In Ram Heavy Duty trucks, the Cummins generates from 350 to 420 hp and 610 to 1,075 lb-ft of torque, while commercial truck output ranges from 305 to 360 hp and 610 to 800 lb-ft of torque. The F-650 and F-750 medium-duty trucks fitted with the Cummins produced from 200 to 360 hp and 520 to 800 lb-ft of torque.

Ram offers the 2024 model trucks with a high-output version 6.7 mated to the Aisin AS69RC automatic transmission producing 420 hp and a whopping 1,075 lb-ft of torque. If the Cummins 6.7 engine has a weakness, it is the complicated emissions system that includes exhaust gas recirculation (EGR), diesel oxidation catalyst (DOC), and diesel particulate system. Per DieselIQ, the Cummins 6.7 — aside from emissions issues — is an efficient and stout engine with a B10 life (or point where 10% of the engines will fail) of 250,000 miles. The B50, meanwhile, has a life of 350,000 miles.

Volkswagen 1.9 TDI VP Engine

Despite the emissions test scandal often referred to as "Dieselgate" or "Emissionsgate," that began in September 2015 and resulted in the worldwide recall of millions of diesel cars, the Volkswagen TDI (for Turbo Direct Injection), is still considered one of the most reliable diesel engines. Volkswagen designed the 1.9 TDI VP Engine (so designated by the VP, German "Verteilerpumpe," or "distributor pump" on the injection pump), with simple accessories resulting in exceptional durability. Volkswagen offered the first-generation engine in 75, 90, and 110 hp versions, all featuring a fuel delivery system using a Bosch rotary pump. A variable geometry turbine and a floating flywheel (on the newer models) contributed to the engine's performance and reliability.

Offered in several VAG (Volkswagen Audi Gruppe) models from 1991 to 2010, the 1.9 TDI gained notoriety for its low fuel consumption and excellent dynamics. Despite its reputation for reliability, the 1.9 TDI engine suffered from excessive vibration and rattling prevalent in the smaller, less expensive cars, that transmitted to the cabin at the steering wheel and pedals.

In the late 1990s, Volkswagen installed a pump-spray injection system that helped achieve higher injection pressures and improved fuel efficiency. However, the new system failed to reduce the engine vibrations. VAG manufacturers installed oil-filled rubber engine mounts to help reduce the shaking. The 1.9 TDI engines were exceptionally noisy, especially when installed in the base-model cars, and most often at low speeds. At higher speeds, the noise is less bothersome (most likely partially drowned out by normal road noise).

Toyota 1.4 D-4D Engine

Although troubled with problems from the earlier 2.0 and 2.2 AD family of diesel engines, Toyota succeeded in manufacturing one of the best diesel engines made in recent years. The 1.4 D-4D engine is rated at 450,000 km and features a common rail injection with a Denso or Bosch injector. Installed in the Toyota iQ, Yaris, Toyota Auris, Corolla, Urban Cruiser, Verso-S, and Mini One D, the 1.4 D-4D is Toyota's smallest diesel engine. It features a variable geometry turbocharger, intercooler, common rail injection, EGR valve, and an aluminum block (the first Japanese-made diesel engine with an aluminum block).

The 1.4 D-4D produced only 75 hp and 125 lb-ft of torque but achieved excellent fuel efficiency at 47 mph or better depending on the car. In 2004, Toyota introduced a new variant, increasing the power to 90 hp and the torque to 150 lb-ft, and in 2008 upgraded the engine to meet the Euro 5 emissions standard. The automaker installed piezo injectors, an EGR valve, and a soot particle filter. Toyota equipped the Yaris, QK, Aurisie, Verso, and Urban Cruiser with the new engine.

The 1.4 D-4D engine has some problems that are not atypical of other diesel engines, such as a noisy drive chain, excessive oil consumption, or problems with the engine control unit (ECU). However, its overall reliability is among the best in the industry. Per Mlfree, Toyota engineers have developed a simplistic engine, which provides good stability, low failure rates, and easy maintenance. Failures are rare, even in the oldest cars with 1.4 D-4D engines, despite already high mileage.

Hyundai / Kia 1.6 CRDi Engine

The 1.6 CRDI engine is part of a series of five Korean diesel engines with two-camshaft cylinder heads and four valves per cylinder. Both Kia and Hyundai use the engines in their European market cars and Continuous Injection System (CIS) vehicles. Introduced in 2007, the 1.6 CRDi is part of the U family of engines and features a Common Rail injection with Bosch injectors, a double mass flywheel, a variable geometry turbocharger, and a DPF filter (after 2009 in the second generation). Depending on the version and year of manufacture, the engine power varies from 90 to 136 hp. The diesel engine is used in the Hyundai i20 and i30, as well as Accent, Kia Cerato, Venga, Soul, CEE'D, and Sportage makes.

The 1.6 CRDi engine has demonstrated exceptional reliability since its introduction and AutoSpruce gives it a durability rating of 500,000 km. The first-generation engine benefits from its lack of a floating flywheel, which in other diesel engines has contributed to high repair costs.

The early 115 hp engines suffered from a loss of power from a malfunctioning turbocharger. Kia resolved the issue by changing the software on the engines produced from 2006 to 2009. The CRDi engine has also experienced some problems with the Bosch injection system, however, system elements are repairable, keeping total repair costs to a minimum. Drivers who use their cars mostly for city driving may have issues with a clogged DPF filter. None of these problems are serious enough to tarnish the exceptional durability rating of the 1.6 CRDi engine.