How The Opposed-Piston Engine Could Be The Answer To Near-Zero Emissions

Remarkable innovations have been made to automotive technology since Karl Benz introduced the world to the "Motorwagen" in 1866 and Henry Ford gave rise to the American auto industry with the Model T in 1908. Yet despite the progression from hand-crank starters and smoke-belching straight pipes to push-button electronic ignition and smog-friendly hybrids and EVs, the internal combustion engine has remained somewhat unchanged in its fundamental design, with a structure incorporating a single piston per cylinder and a valve train housed within a cylinder head.

A sea change is on the horizon, however, as a revolutionary opposed-piston diesel engine designed by physicist Dr. James Lemke, and built by his company, Achates Power, has entered fleet service with the Wal-Mart corporation under the hood of a Peterbilt model 579 tractor.

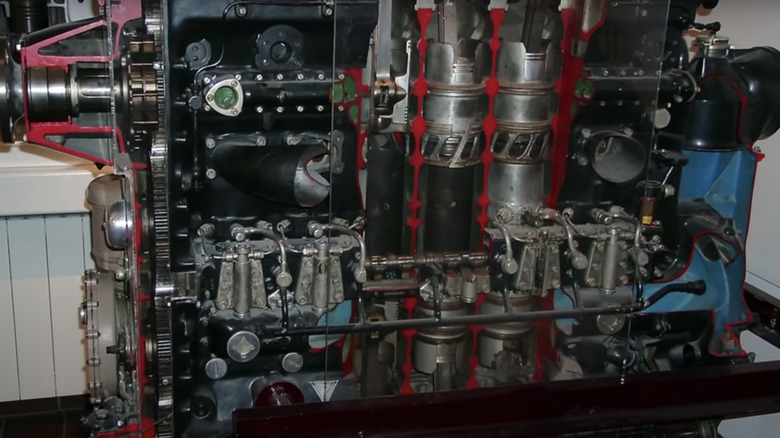

Lemke was far from the first person to propose or build an opposed-piston motor. The Fairbanks-Morse model 38 8 1/8 diesel engine has powered submarines and surface ships since the 1930s, and both Gobron–Brillie and Arrol–Johnston put gas-powered opposed piston engines in race cars earlier in the century. While a standard four-stroke engine relies on combustion from a spark plug to apply downward pressure on a piston and synced valve timing to allow for air and fuel to be brought into the engine cylinder and exhaust gases to be expelled, an opposed-piston engine literally turns this concept on its side.

The opposed-piston design saves fuel and is inherently emissions-friendly

In an opposed-piston engine, two pistons are placed at opposite ends of the cylinder, and the fuel is combusted in the space between them. The design requires no cylinder head or valve system, reducing excess heat and moving parts relative to a traditional four-stroke engine. Achates touts its 10.6-liter engine as being compliant with 2027 California Air Resources Board (CARB) standards, which require a 90% reduction in NOx emissions compared to current standards. According to the manufacturer, Achates' opposed-piston engine also puts out about 10% less carbon dioxide emissions than a traditional four-stroke engine.

These gains are achieved largely through improvements in efficiency that result from the engine's simple design, which will also make the Achates motor cheaper to service and maintain over its lifespan. Lemke, who holds 114 patents and refers to himself as a "serial entrepreneur," developed the Achates engine as an improvement on the Junkers Jumo aircraft engine that debuted in 1890. "It had an efficiency that exceeded any engine that had ever been made before," Lemke said in a promotional interview.

James Lemke never got to see his engine put to use in fleet vehicles

The Junkers Jumo engines were made obsolete by the advent of jet engine technology, but Lemke said he became intrigued while reading a book about the Junkers engines during a trip to Mexico in 2001. Lemke said he immediately saw the potential the opposed-piston design held for modern vehicles and pointed out how the streamlined opposed-piston layout led to a cleaner-burning motor. "Many engines have a sweet spot where they get maximum efficiency," Lemke explained. "If you're off that, efficiency falls off very rapidly. Ours is a very flat plot that is about the same efficiency everywhere. Any application of diesel at the present time will benefit from this configuration by better efficiency and cleaner performance. Ours is the cleanest engine, about 20 to 30 percent more efficient than any diesel ever made."

Dr. Lemke died in 2019 at the age of 89, so sadly he never got to see the Achates-powered Peterbilt tractors hit the road, but his legacy could hopefully live on in the form of a cleaner-burning, more fuel-efficient engine that might someday be christened the Lemke in his honor.