8 Revolutionary Engines That Changed Aviation Forever

Crewed flight is unquestionably one of the greatest achievements of the 20th century. Not only did it significantly expand the scope of what we, as humans, can achieve, but it also revolutionized the way we trade, the way we communicate, and of course, the way we travel. While much is said about the pioneers and aircraft that represented successive generations of aviation evolution, without the internal combustion engine (which later included jet engine technology), none of it — quite literally — would have gotten off the ground.

There are relatively few players in the aircraft engine manufacturing industry, dominated by U.S. and European brands. Some even form alliances to get the best results. In commercial aviation, success is usually measured by how safely and economically an aircraft can transport goods and passengers, paying close attention to emission levels and engine noise, while in military service and space travel, their functions are more task-specific. One thing all have in common, however, is that the engine is the beating heart of each aircraft, and through the years, it has played a pivotal role in the development of this modern technological marvel.

The following are the engines that made the biggest waves in aviation, revolutionizing not just the industry itself but also the way we live our lives and view the world around us. From a field in Ohio to the outer reaches of the solar system, these machines tell the story of how we ascended to the skies.

Wright 1903

Combustion engines had been used to power automobiles for over 40 years by the time Orville and Wilbur Wright conducted the world's first human-crewed flight above Huffman Prairie outside of Dayton, Ohio. While this historic event occurred in 1904, it was the Wright 1903 engine that made it possible. This was a bespoke design, as nothing suitable or modifiable then existed.

The brothers' engine had to meet certain specifications if they were to achieve their goal. By their estimation, it had to produce at least eight horsepower and weigh a maximum of 200 pounds. While this power-to-weight ratio may sound puny by today's standards of engineering, at the time, it required a clean slate approach, and the engine was designed and built from scratch using only a metalworking lathe and drill press. The final product was made of cast aluminum and iron, weighing 180 pounds and producing 12 horsepower, smashing the requirement by some margin.

Immediately following this crowning achievement, the Wright brothers went on to have a very successful engine manufacturing company, first as Wright Engines and later as Wright Aeronautical. Wright Aeronautical had a storied history, first breaking the world speed record in 1919 before supplying Charles Lindbergh's Spirit of St Louis with an engine for his own historically significant 1927 flight from New York to Paris. Yet it was the original 1903 engine, with its groundbreaking strong and lightweight aluminum alloy construction, that paved the way for the creation of all future aircraft engines.

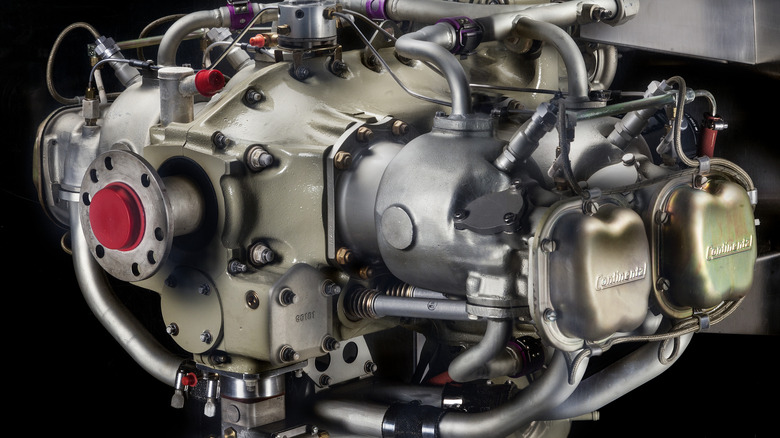

Continental A40

As aviation became mainstream, light aircraft began taking on roles as passenger vehicles and freight carriers, such as mail planes, and being used for business and personal use. Most engine development in the mid-20th century focused on heavy radial engines and prioritized speed and payload, and there was a requirement for smaller engines for smaller craft. The Continental motor company started producing the A40, a four-cylinder, air-cooled engine that was a perfect fit for light planes, including the new Taylor Cub design, as it weighed just 155 pounds and produced 40 horsepower.

The Taylor Cub was a precursor to the Piper Cub, which became highly popular in the 1930s, with production accelerating during World War Two. Cubs were the primary training aircraft used in the Civilian Pilot Training Program at the outbreak of the war, and they were used in military service as reconnaissance, transport, and spotting planes. A Cub was built every 20 minutes to facilitate this, and the Continental Motors company was thriving.

Larger variants of the successful A40 were required as the demands of the aviation industry changed over time, and the 90-horsepower C-90 and 200-horsepower A-200 were also popular units for Continental. So successful and reliable were these engines that they still serve as the basis for most modern light aircraft engines, with these smaller planes promoting flying as a hobby as it became less of an elitist pursuit. In this regard, the A40 made piloting aircraft more widely available to the masses.

Rolls-Royce Dart

When you hear the name Rolls-Royce, most of us think of its line of luxury automobiles. However, its long history of aircraft engine manufacture is equally successful, and it is still one of the major players in the aviation industry. The Rolls-Royce Dart turboprop engine, introduced in 1946, was an excellent example of uncomplicated design and quality engineering, combining the power of jet engines with the efficiency of propellers.

You could be forgiven for thinking that Rolls-Royce named the Dart after the arrow-like projectile. However, the company has a tradition of naming its products after British rivers, in this case, the River Dart in the south. The engine was a major player as a facilitator of early commercial intercontinental travel and was in production for an impressive 40 years. First installed in the Vickers Viscount, it went on to be used by global manufacturers, including Grumman, Fokker, Avro, and Breguet.

A turboprop is similar to a jet engine, but as the name suggests, it is fronted by a regular propeller that draws air into the body of the engine, where it is compressed, passed into a combustion chamber where it mixes with ignited fuel, and is thrown out of the back as a high-energy jet stream. This system proved to be perfect for medium-range aircraft, such as the Vickers Viscount. Importantly for commercial aviation, it proved more economical than a regular jet engine, going on to clock over 170 million flying hours in its long and successful tenure.

Pratt & Whitney JT3

Jet engine technology wasn't practical until the mid-1930s, before which it was deemed too inefficient for long-haul subsonic flight. While jet engines were not widely used during World War Two, development accelerated after 1939 with the invention of the Heinkel He178, the first successful jet aircraft upon which most jet engines were subsequently based, including the Pratt & Whitney JT3.

The JT3 family of turbofan engines was first developed in 1950. It was soon given the U.S. Airforce designation TF133, and in 1955 it was installed on perhaps its most notorious aircraft, the B52 long-range heavy bomber. Eight JT3 engines power the B52, which is still in service today, having clocked over 72 million flight hours.

Later, commercial aircraft fitted the JT3, including the Lockheed C-141 Starlifter and the Boeing 707. It was favored for its low noise, low emissions, and low fuel consumption. It occupied a sweet spot between the turboprop and turbojet engines of its day, and was ideal for fast, economical subsonic flight but eliminated the scream of the turboprop's compressor and the deafening note of the turbojet's exhaust. Instead, the JT3's turbofan sent enough air through the engine to provide enough thrust but rerouted a quantity around the engines; hence the turbofan became known as a "bypass engine." This practicality led the turbofan family of engines, including the Pratt & Whitney JT3, to become today's dominant commercial jet engine. It evolved to produce supersonic variants, some of which are used in military aviation.

General Electric CF6

Following the Pratt & Whitney JT3, the General Electric CF6 was introduced during the start of the 1970s as commercial aviation continued to expand. Following the success of the Boeing 747 in the 1960s as the first "Jumbo Jet," the CF6 was developed specifically for widebody aircraft as the aviation industry evolved at that time.

One of the most efficient engines ever produced, the General Electric CF6 engine transformed commercial air travel. It has been installed on popular commercial aircraft including the Airbus A300, A310, and A330; and the Boeing 747, 767, and MD-11, as well as the military aircraft Kawasaki C-2, McDonnell-Douglas DC-10, and the Lockheed-Martin C-5M Super Galaxy. The General Electric CF6 family of engines is used in almost 70% of the widebody aircraft currently in operation and has consistently improved over time. It now provides 30,000 pounds more thrust than the first generation CF6, is as much as 15% more fuel efficient, and can fly three times longer between overhauls. This impressive performance has led to one variant, the CF6-80C2, having a larger installed base than any other widebody engine.

The CF6 could be compared to the Swiss Army Knife, Zippo lighter, or Fender Stratocaster guitar as a dependable design that has fundamentally stood the test of time, albeit with a few revisions along the way. As international travel became publicly viable and the industry shifted to necessitate bigger planes with better fuel economy, General Electric delivered the perfect solution for the "Jet Age."

Rolls-Royce Trent

The Rolls-Royce Trent family of engines has been in service for over a quarter of a century and continues to go from strength to strength. Just as its namesake British river is subject to intense yearly flooding, the Trent engine has flooded the market as the turbofan power unit installed on some of today's most popular widebody aircraft, including the Boeing 777 and 787, and the Airbus A330, A340, A350, and A380.

This is another high-bypass turbofan engine, much like the Pratt & Whitney JT3, whereby air is routed around the engine, making it quieter and more efficient, compared to a zero-bypass engine where all air is delivered through the turbine. Also, like the General Electric CF6, it has been produced in several variants for different applications, including non-aircraft industrial and marine purposes.

Rolls-Royce is second only to General Electric among the biggest providers of aircraft engines, with Pratt and Whitney coming in third. But thanks to the versatility and long-range capability of its Trent engines, it has revolutionized international travel, as it allows providers to fly in diverse conditions from intense desert heat to sub-zero arctic environments and to navigate longer routes. These include the longest commercial flight currently in operation, from New York's JFK to Singapore International Airport, at 18 hours and 50 minutes.

CFM International CFM56

The single-aisle aircraft segment has the most significant marketshare of any at around 56%. While the aforementioned widebody engines are impressive in their capability, versatility, and sheer amount of power they produce, the workhorses of the industry performing short-haul national and international flights clock up the most miles year-round. CFM International is a joint venture between General Electric and Safran Aircraft Engines of France, and its CFM56 engine powers planes that include the ubiquitous Boeing 737 and Airbus A320, making it the backbone for popular medium-capacity commercial flights.

Typically for a large commercial airline engine, the CFM56 is a turbofan. It has been developed over 40 years and continues to be upgraded, with the latest versions, the CFM56-5B PIP and CFM56-7BE, offering improvements to fuel economy, maintenance overheads, and emission levels. Many features make it attractive to suppliers, including its durability, reliability, and ease of repair. Ultimately, its low cost to run is its most appealing feature.

The CFM56 is the most widely-used turbofan engine by a considerable margin, with almost 33,000 built and more than one billion flight hours served. It supplies more than 600 operators worldwide and has contributed to making flights more affordable, practical, and economical. There is no doubt that CFM International's CFM56 engine changed aviation forever, as anyone who has ever flown on a budget flight will attest to.

Reusable Solid Rocket Booster

Following the Space Race of the 1950s and 1960s, a requirement was identified for a reusable low-orbit spacecraft that could launch satellites, service other spacecraft, and act as a laboratory. This would become known as the Space Shuttle. One of its defining features was its Reusable Solid Rocket Booster. Unlike previous rocket engines, which were discarded and hit the ocean at great speed before sinking, the Space Shuttle's engines could be recovered, having parachuted gently to a safe splashdown not far from the launch site.

Variously manufactured by Pratt and Whitney and an alliance of Lockheed Martin and Boeing, this 149-foot-long behemoth produced 6.6 million pounds of thrust and reached peak power in two-tenths of a second. It required over 1,000,000 pounds of propellant and would burn for two minutes — the time it took to reach an altitude of 28 miles at 3,100 miles per hour. Once the fuel was expended, it would be separated from the Space Shuttle's external tank using electrically fired explosions before deploying three 136-foot wide parachutes after re-entry.

Space travel became continuous with the construction of the International Space Station. Over time, the Space Shuttle's primary role became servicing the Space Station. The last three orbiters, Endeavor, Atlantis, and Discovery, were decommissioned in 2011, with commercial spacecraft such as the SpaceX Dragon 2 and Boeing Starliner filling the role. Meanwhile, NASA's Orion spacecraft will use lessons learned from the Shuttle Program to take humans further into space than ever before.