This New Tire Technology Could Keep You Out Of Big Trouble

Air-filled tires have been a thorn in the sidewall for as long as they have existed, and many companies have taken a crack at solving the problem of flat tires: suspension to compensate, tire sealant, and offroad moose inserts. Regardless of how successful these technologies were at solving the flat-tire problem, though, they all had their drawbacks.

One of the more recent and more successful implementations of anti-flat technology, run-flat technology, is part of the tire's design, instead of being an aftermarket addition. Rather than trying to patch the hole after the fact, or trying to prevent the air from escaping some other way, run-flat tires simply allow the tire to run empty by having reinforced sidewalls and bracing in the tread area that can take the weight of the vehicle when a puncture occurs (according to Bridgestone). While run-flats are a good solution, the airless or low-pressure runtime is limited to 50 miles at a maximum speed of 50 mph.

Despite their limitations, run-flats come pre-installed on many luxury vehicles nowadays, especially since a lower number of cars actually come with spares anymore, according to Cars.com. Now, Bridgestone and Dow are proposing a new solution that's also built into the tire from the factory and is supposedly lighter, more effective, and more eco-friendly than traditional solutions.

Imagine a tire that stretches instead of rupturing

According to a press release, The Dow Chemical Company plans to revolutionize tire sealants using a new silicone material called SiLASTIC SST-2650 Self-sealing Silicone. The silicone-based sealant is a two-part mixture that is applied to the inside of the tire during the manufacturing phase, and Dow has worked with Bridgestone to implement the technology in B-SEALS.

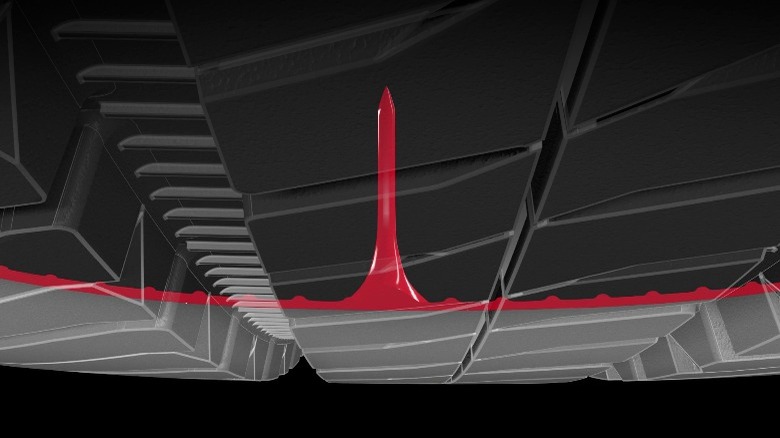

The sealant is essentially a layer of durable, ultra-flexible silicone applied to the inside of the tire. When the tire hits a nail that penetrates the tread, the silicone on the tire's interior flexes around the nail and then fills the hole once the foreign object is removed, holding pressure and allowing for repair later. Dow claims that the material properties allow it to return to its original shape to fill the hole left by the nail whether the nail is removed immediately or after a significant delay.

While Dow advertises the technology as fast-curing, the technical data sheet indicates that curing time is up to seven days, which will impact the manufacturing time for tires using this technology, since the U.S. Tire Manufacturers Association claims that the average light-vehicle tire cures in 12 to 15 minutes. The added cure time simply means that Bridgestone will have to adjust its curing and warehousing processes to accommodate B-SEAL tires. According to Bridgestone, unlike traditional tire sealant gels or liquids, B-SEALS can be easily removed from the inside of the tire, which is essential for recycling.