GE Researchers Create New Prototype Traction Motor For Hybrid And Electric Vehicles

GE has announced the creation of a new world-class traction motor for hybrid and electric vehicles. The new prototype electric motor delivers higher power density and better acceleration efficiency in a smaller frame at a lower cost than existing electric motors. The goal for GE is to extend the range of electric vehicles and reduce fuel consumption for hybrids using the new motor.

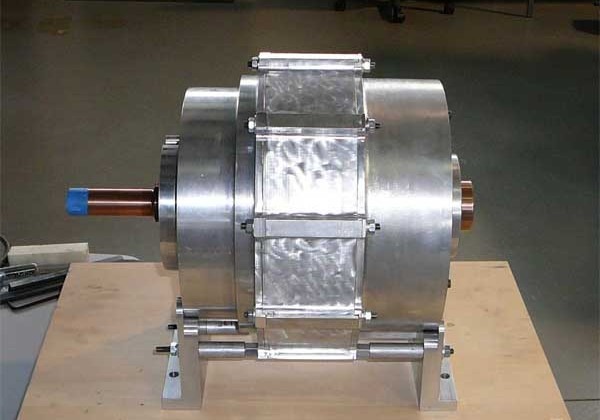

GE notes that the new electric motor has almost twice the temperature tolerance of a conventional hybrid-electric motor and doesn't need a separate cooling system. The elimination of a separate cooling system allows the vehicle to be lighter, which directly translates into longer driving distance. The new electric motor is a prototype Interior Permanent Magnet traction motor that was developed as part of the $5.6 million US Department of Energy project to extend the range of DVDs and hybrids.

The prototype traction motor operates at a peak power level of 55kW and exceeds state of the art motors in the same class in several areas. The motor has nearly twice the power density offering better acceleration compared to similar motors and is 3 to 5% more efficient. The motor also achieves the required torque using lower DC bus voltage as low as 200 V versus 650 V and other motors. The GE electric motor is designed to be cool with normal engine coolant in a hybrid vehicle rather than needing its own dedicated cooling system.

"This is a significant accomplishment. We at GE are pushing the boundaries to build more robust, yet more efficient motors for hybrid and fully electric platforms," said Ayman El-Refaie, Electrical Engineer, in GE Global Research's Electrical Machines Lab. "We have built a motor that is substantially more powerful than what's commercially available now, all while improving efficiency by up to 5%."