How Did The Knight Sleeve Valve Engine Work & What Were Its Disadvantages?

Most modern gasoline and diesel-powered engines found in the cars and trucks seen on today's roadways rely on the four-cycle-engine principles developed in the late 1800s by Nikolaus Otto, Gottlieb Daimler, and Wilhelm Maybach. While two-cycle engines exist, they didn't fare as well as the four-cycle version for automotive applications. The four-cycle engine, or Otto-cycle as it's often called, describes the four piston strokes (two crankshaft revolutions) required to produce power: Intake, Compression, Power, and Exhaust. The Knight sleeve valve engine used the four-stroke Otto-cycle system present in most modern vehicle engines.

Starting with the piston at the top of the cylinder, the crankshaft's rotation pulls it down as the intake valve opens to allow the air-fuel mixture into the cylinder. At the completion of the first stroke, the piston is at the bottom of the cylinder and the spinning crankshaft pushes the piston up for the compression (second) stroke with the valves closed. With the piston at the top, the compressed air-fuel mixture is ignited by the ignition system, the rapidly expanding burning fuel forces the piston down, spinning the crankshaft completing the third stroke. As the piston returns to the top of the cylinder, the fourth stroke, the burned fuel is pushed out of the cylinder through the exhaust valve.

[Featured image scanned by Andy Dingley via Wikimedia Commons | Cropped and scaled | Public Domain]

What made the Knight sleeve valve engine different?

Whereas most modern four-cycle engines use overhead valves operated by pushrods, single overhead camshafts or dual overhead cams, past engine designs employed other valve systems to allow the flow of gases through the combustion chamber. Much like the battle raging between electric cars and gas engines today, consumers chose the best valve design through their buying decisions guided by personal experience, expert opinions, and advertising.

According to the Jaguar Heritage Trust, Charles Yale Knight, an American engineer born in Indiana in 1968, began working on a sleeve valve engine design based on slide valve engine principles he'd learned as a young man while repairing the Otto engine powering his father's sawmill. His first experimental engine, built in 1903, led to a functional prototype in 1905.

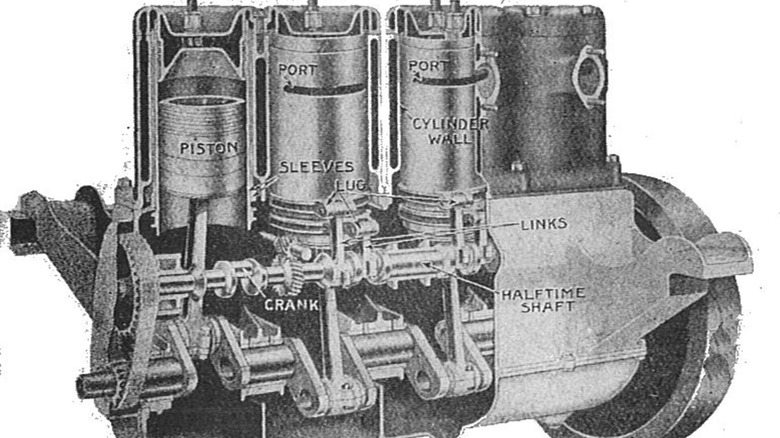

Knight's sleeve valve engine had two sliding sleeves per cylinder, each connected to a "half-time shaft" by connecting rods. The half-time shaft, powered by a belt from the crankshaft, slid and twisted the sleeve valves to align with the cylinder's intake and exhaust ports in-time with the four-stroke process.

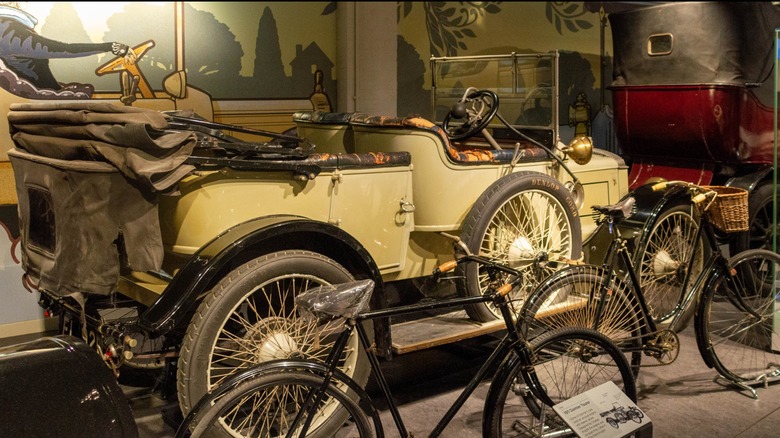

In April 1908, Knight licensed his design to Daimler for further development and production, and by September, Daimler began installing the single sliding-sleeve valve "Silent Knight" engine in its cars for sale in England and the U.S.

[Featured image by Marty B via Wikimedia Commons | Cropped and scaled | CC BY-SA 2.0]

Disadvantages of the Knight sleeve valve engine

In the early 1900s, the sliding sleeve valve engine had some advantages over tappet valve engines of the time. For example, sliding sleeve valve designs allowed larger intake and exhaust ports, a central spark plug location, no valve springs, and the carbon (or coke) build-up from burning low-quality gasoline (and engine oil) actually improved the sleeve valve engine's operation instead of the "de-coking" tappet valve engines required after 20,000 miles of driving.

In the end, the sliding sleeve valve's disadvantages outweigh any advantage gained by the design. The sliding sleeve design made sealing the engine difficult. With more passages between the combustion chamber and the crankcase, engine oil found its way into the cylinder. This was especially apparent on engine start up, often resulting in a cloud of smoke surrounding the car.

The sliding sleeve valve engine ultimately lost its battle with tappet valve designs as refineries produced increasingly higher quality gasoline. Higher quality fuel reduced the tappet valve engine's need for frequent de-coking and lower oil consumption, resulting in a less smokey drive.

[Featured image by Michael Gaylard via Wikimedia Commons | Cropped and scaled | CC BY-SA 2.0]