5 Of The Most Reliable Engines Ever Made By Pontiac

Pontiac began in the 1920s as a brand that helped define General Motors' mid-tier strategy. Over the years, it gained a reputation for building sturdy and powerful engines that have left an everlasting mark on automotive history. Initially, Pontiac engines like the early straight-six flatheads were reliable but unspectacular. They were foundational, offering dependable service without breaking new ground in engineering. However, as the decades passed, Pontiac developed a more distinct personality, particularly in the postwar era. The advent of V8 engines marked a momentous transition, transforming Pontiac from a manufacturer of reliable but ordinary engines to a powerhouse of performance and innovation.

What makes an engine reliable? Key characteristics include durability, consistent performance under various conditions, and minimal repair requirements. Engines from the V8 era particularly exemplify these characteristics. They were designed to last, and several have survived decades of service. Reliability also involves an engine's capacity to respond to performance demands while maintaining longevity. Pontiac engines met and frequently exceeded these expectations with ingenious engineering solutions.

Despite Pontiac's closure, the spirit of its engines lives on. Many of these powertrains are still cherished by enthusiasts and collectors for their historical significance and long-lasting performance. These are five of the most reliable engines that Pontiac ever made.

Pontiac OHC Sprint Six

The short-lived OHC Sprint Six (1966-1969) is unique in that it was built when most domestic manufacturers preferred tried-and-true classic engine designs. But, unlike the more common overhead valve (OHV) arrangements at the time, Pontiac used the overhead cam (OHC)design.

The engine was available in two versions: a base version with a one-barrel carburetor that produced 165 horsepower and a high-performance Sprint version. The latter included a four-barrel Quadrajet carburetor, a high-lift cam, and a split exhaust manifold. It first produced 207 horsepower and subsequently 215 horsepower as the engine was developed and expanded from 230 to 250 cubic inches.

The reliability of this engine came from the fact that it was maintenance-friendly. The engine drives the camshaft with a fiberglass-reinforced toothed belt, doing away with the typical noisy gears and chains used at the time. It also lowered the wear and tear that was typical with earlier systems. Because it had fewer moving parts, maintenance was relatively easy. It only required the regular checkups and replacements that local mechanics or owners could easily handle.

Another contribution to reliability was the tough design and materials. The lower engine block was skirted to reinforce the lower end and increase structural integrity. Its camshaft carrier was composed of die-cast aluminum, posing less wear risk than standard bearings because it sat directly on the alloy housing. It's hardly surprising that this engine is often called one of the most underrated Pontiac engines ever.

Pontiac 428

The 428, which was manufactured between 1967 and 1969, was mainly used to power full-sized vehicles like the Bonneville and Catalina, but it was also used in muscle cars like the GTO and Firebird through custom installs by dealers such as Royal Pontiac. This was thanks to the 428 being a magnificent example of Pontiac's inventiveness in getting over GM's mid-size engine displacement regulations. The engine was really powerful, too. In its final version, it was capable of producing between 360 and 390 horsepower (the HO version of this engine even makes it to the list of Pontiac's most powerful engines). This was great for all the enthusiasts working on projects and looking for speed, but did the 428 perform as well when it came to reliability? The short answer is yes.

The Pontiac 428 was built to last, using high-quality materials like a stronger steel alloy and Armasteel cast. This earned it a place on our list of the 10 most reliable General Motors engines ever made. The engine had strong cylinder heads and a crankshaft that could really withstand the tests of time and performance demands. With components like a large-journal crankshaft and interchangeable parts with other Pontiac V8s (400 and 455), the engine was both strong and easy to maintain and modify.

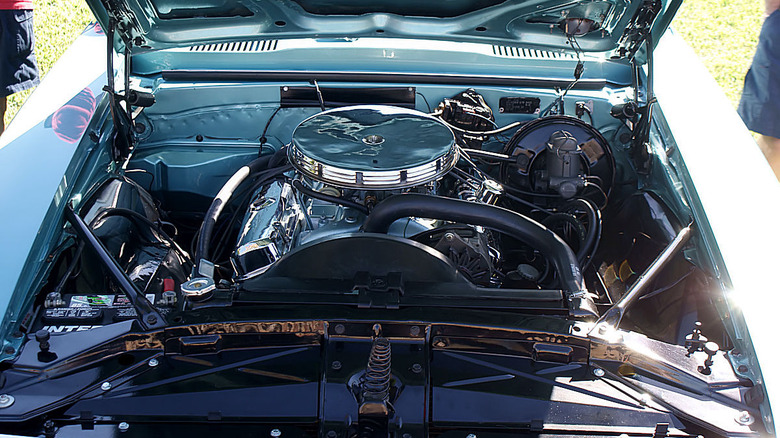

[Featured image by Mr.choppers via Wikimedia Commons | Cropped and scaled | CC BY-SA 3.0]

Pontiac 421 Super Duty

The 421 Super Duty has an interesting story set against the backdrop of the heated horsepower wars of the early 1960s. Introduced late in 1961, this engine made major improvements over Pontiac's previous 389 cubic-inch archetype. There are many things that made the Pontiac 421 Super Duty engine impressive, so let's go over the highlights.

The Super Duty, with its massive 421 cubic-inch displacement (about 6.9 liters), had excellent specs, including a forged steel crankshaft, aluminum pistons, and strong connecting rods. Its power output was rated at 405 horsepower, but tests frequently showed rates surpassing 460 horsepower and torque ratings over 425 lb-ft. Powerful? Yes, but they were also designed to last and withstand the demands of high-speed racing.

This engine powered various Pontiac vehicles, including the Catalina and Grand Prix. These even had extra features like dual Carter four-barrel carburetors and free-flow cast-iron headers. These additions allowed them to run quarter-mile times in the 13-second range at speeds exceeding 100 mph. This reliable architecture helped Pontiac cars win NASCAR and drag racing events in the 1960s.

The 421 did make it to the general public, and while it was reliable overall, it had its share of issues and was far from invincible. The model shared common faults most high-performance engines had back then, like high minimum idle speeds and sensitivity to colder conditions. Still, its impressive specs and overall quality earn it a spot on this list.

Pontiac 400 V8

Introduced in 1967, this 6.6-liter immediately became the engine of choice for some of Pontiac's most famous vehicles like the Firebird and GTO. Its overhead valve design, as well as bore and stroke dimensions of 4.12 inches and 3.75 inches, allowed for a high displacement and significant power output ranging from 180 bhp at 3,600 rpm to 370 bhp at 5,500. But just as much as power, this engine was built with longevity in mind, having strong components that can handle extreme stress and wear — the cast-iron block and head, for example.

Its capacity to withstand tremendous mileage while maintaining performance is a credit to its engineering. Case in point, a '67 GTO owner under the username geeteeohguy wrote on the GTO Forum that this engine, originally rebuilt at 173,000 miles in 1988, smoothly powered through a 2,700-mile road trip without any issues, using less than half a quart of oil despite having nearly 90,000 miles on the rebuild. He went on to say that the car had over 260,000 total miles at the time of writing. Reliability like this is usually attributed to the 400's use of high-quality materials and a simple design. Regular maintenance is also key, especially in areas prone to wear, like the cooling system and valve train. Take good care of it, and this engine can operate for decades after its anticipated service life.

[Featured image by Valder137 via Wikimedia Commons | Cropped and scaled | CC BY 2.0]

Pontiac 389 V8

The Pontiac 389 V8 engine, introduced in 1959, was a crucial step forward in the evolution of muscle automobiles. As the name suggests, it has a displacement of 389 cubic inches (6.4 liters) and was built with a cast iron block and heads. This build quality is one contributing factor to its reliability. Depending on the configuration, horsepower ranged from 215 to 368 hp and torque from 380 to 429 lb-ft. Interestingly, the Tri-Power carb configuration on select models was typically the most powerful variant.

Pontiac used the 389 in various vehicles, including the midsize Tempest, from which the iconic GTO was born, and full-size models like the Bonneville and Catalina. But the special configurations that the 389 came in, like the Super Duty and the high-performance 420-A, had the most attention. These were race variations with features like a four-bolt main engine block and forged steel crankshafts and connecting rods. These improvements helped Pontiac perform in NASCAR, as the Super Duty variant won seven races during the 1960 season.

One major issue holds the 389 back from being a completely reliable Pontiac engine. The nylon-coated OEM cam timing gear, which tended to deteriorate and flake off, had the potential to cause engine damage. Getting ahead of this problem is as simple as changing oil at the specified times, but it's still a big hit to an otherwise reliable engine.