Here's How The U.S. Navy Fights Rust On Its Ships (And Why It Costs Way More Than You'd Think)

The U.S. Navy spends billions of dollars on the research, design, and construction of new vessels — and the costs don't just end once the ship is out of the shipyard. You might think of maintenance as the fixing of battle damage but there's actually a much more mundane and even more inevitable enemy to deal with: rust.

The combination of iron, water, and oxygen will always result in rust, and if left alone, it can damage a ship enough to shorten its service life. Add salt into the mix and the process speeds up, making rust maintenance a constant effort for sailors all over the world. In the U.S. specifically, the Navy spends as much as $6 billion a year on fighting rust — not only on the ships themselves but also on the helicopters and fighter jets that travel on them.

To make matters worse, it's not a problem that's likely to go away anytime soon. Though there are multiple conferences, foundations, and organizations dedicated to the research and development of anti-rust solutions, there's no low-effort, low-cost, and time-effective product in existence yet.

What is rust?

Rust, or iron oxide, is the product of a common chemical reaction that we see all over the place — from our showers to the bike we left out in the rain or the old streetlight outside. Naval vessels are made primarily of steel, an alloy of iron and carbon. Although they use HSLA (high-strength low-alloy) steels that are designed for strength, weldability, and corrosion resistance, ships still require near-constant maintenance to keep rust at bay.

The maintenance process isn't easy, either. Sailors need to prepare areas by wiping them with water and rags and then using a needle gun to dislodge rust from the ship's surface. Next, they need to wipe it down again and use a sander to remove the rough edges. After wiping down yet again, sailors apply two coats of primer and then sand it down to create a level surface. Finally, after hours of work, they can add the special rust-resistant paint that helps to protect the metal from the elements — and costs around $250 per gallon. But this is just the regular work that sailors need to keep up while they're at sea. When boats go to port or the dry dock, even more intense repairs are carried out to undo the rust's work.

When crews don't stay on top of preservation tasks, they can end up with holey decks and bulkheads and a lot more work on their hands the next time they dock.

How much rust is too much rust?

It's not just the parts of a boat that stay underwater that are susceptible to rust. The hull, the decks, and the fighter jets on a carrier — all of them are constantly met with salt spray that can and will cause rust. So when you think about how big these boats are, how rust appears just about everywhere, and the process required to get rid of it, keeping a boat pristine seems almost impossible.

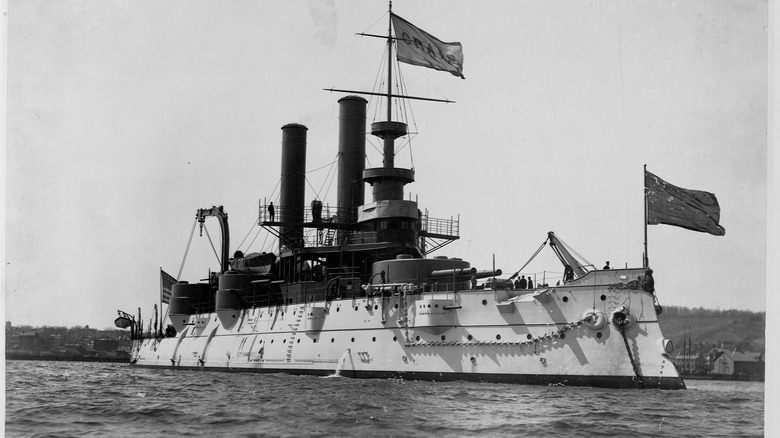

However, that's what most crews are supposed to aim for. While surface rust isn't going to put the boat and its crew in danger, it doesn't look good. The red, brown, and orange hues against the haze gray hull paint are painfully noticeable, and this is more of a problem than you might think. The U.S. Navy has been one of the core ways America has shown its strength since its founding, with Roosevelt's Great White Fleet traversing the entire globe to display that naval power. The hulls were literally painted white and maintained to perfection by the crews. It was a way to instill confidence in America's allies and fear in its enemies.

Recent rust problems

Recent photos of U.S. Navy ships, however, have been attracting the exact opposite kind of attention. With rust streaks and weathered waterlines on display, citizens and retired Naval personnel worry about how their ships look compared to practically rust-free foreign vessels.

Practically speaking, it's somewhat unfair to expect the U.S. Navy vessels to maintain the same outward appearance as other navies since they deploy fleets all over the globe for extended amounts of time, while other countries stay within their own waters and closer to the docks. But part of being strong is using your superior resources, manpower, and funding to overcome such disadvantages and appear in tip-top shape at all costs. How a ship looks is a point of pride, and it can affect how other countries view the U.S. Navy.

With extensive man hours, expensive paint, dry-dock visits, and so much more going into the fight against rust, it's no wonder that it costs the navy a staggering amount of money. But since building ships out of wood is longer an option (and aluminum didn't work out either), there's nothing to do but keep up the work until a miracle rust-buster comes along.